Did you know that the term ‘supply chain management’ wasn’t coined until the 1980s? And now, it is an integral part of many businesses. In fact, efficient supply chain management (SCM) and business success go hand in hand.

With many companies competing for the same set of consumers, it is critical to exceed customer expectations. That’s where SCM plays a noteworthy role. And the importance of SCM has only been amplified during the pandemic.

So let’s see more about supply chain management and its role in today’s business world.

Table of Contents

What is Supply Chain Management?

What does supply chain management mean? Supply chain management (SCM) refers to managing the flow of goods and services. Also, it includes all the processes that transform raw materials into final products.

In the supply chain, a business forms a network of suppliers who act as ‘links’ in the chain to move the product from the raw materials suppliers to those businesses that deal directly with users. SCM is a complex discipline. Because it combines engineering, logistics, IT, and marketing elements. And all these are intended to increase efficiency and decrease costs.

Also, SCM is a diverse business process. And it involves overseeing several functions and factors, including but not limited to:

- How suppliers procure raw materials

- Suppliers’ warehousing capacity

- Wider reaching logistics management

- Forecasting and supply chain planning based on both historical and real-time data to meet customer demand

- Efficient inventory management

- The entire customer order process, from processing to dispatch and delivery

A well-managed supply chain is extremely dynamic and flexible. In fact, it can meet the ever-changing needs of consumers and the broader market.

Some of the stakeholders in supply chain management are:

- Suppliers

- Manufacturers

- Wholesalers

- Transportation providers

- Logistics managers

- Retailers

SCM is concerned with actively streamlining supply-side activities. Which helps increase customer value & businesses gain a competitive advantage in the marketplace. Moreover, it allows brands and retailers to optimise their prices. Also, they can improve their inventory allocation, and identify potential problems at an early stage.

Supply Chain Management (SCM) VS Supply Chains

A supply chain is one of the organisation’s core activities. It’s a network of individuals, companies, resources, activities, and technologies to make and sell a product or service. And a supply chain starts with delivering raw materials from a supplier to a manufacturer. Then it ends with providing the finished product or service to the end consumer.

On the other hand, supply chain management is defined as managing the flow of goods and services. And it includes processes that transform raw materials into final products. SCM oversees all the touchpoints of a company’s product or service, from production to the final sale. Also, it adds value by increasing efficiency, revenues, and decreasing costs. Overall, it has a huge impact on a company’s bottom line.

What is the Purpose of Supply Chain Management?

What is the purpose of supply chain management? There can be many reasons why a company would pursue supply chain management. Regardless, some primary purposes of the supply chain are –

- Cost control

- Drive customer value

- Efficient allocation of resources

- Effective gathering of information for business decisions

- Fulfil demand faster

- Improve responsiveness

- Risk management

Essentially, SCM affects product and service quality, delivery, costs, customer experience and, profitability. These are also the reasons why supply chain management is so important.

Therefore, the primary goals of efficient supply chain management should be – faster delivery, higher efficiency, and an accelerated cash flow.

Why is Supply Chain Management Important?

Still wondering why supply chain management is important? Or what are the benefits of supply chain management? Here are a few reasons why supply chain management is important –

- Safeguarding supply of raw materials

- Better inventory management

- Better partnerships with distributors

- Adherence to legal and ethical standards

- Better visibility and data analytics

- Better quality control and reduced operating cost

- Shipping optimisation

- Improved risk mitigation

- Stronger cash flow

- A resilient network and more agile business

- Improved customer satisfaction

- More efficient sourcing and procurement

A meticulous, well-managed supply chain can remarkably downsize a company’s operating expenses and drive up profits. Moreover, every aspect of the supply chain can reflect this – from ideation to the marketing and delivering the final product.

Also, supply chain management plays a less recognised societal role. That is, ensuring the physiological necessities like food, energy, medicine, and modern infrastructure are flowing and available.

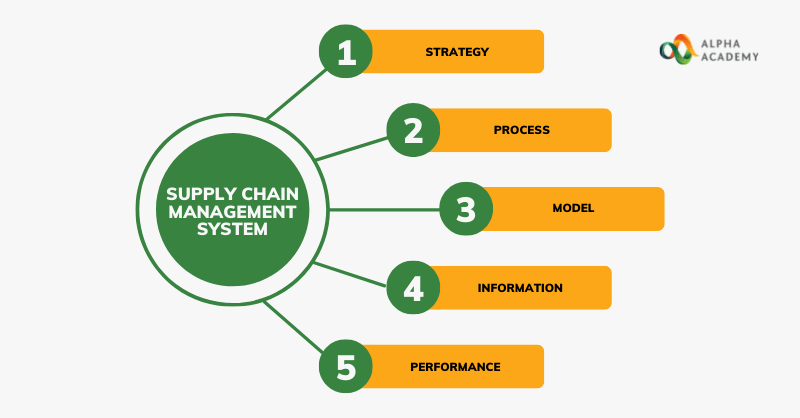

What are the 5 Basic Components of a Chain Management System?

Supply chain management, or SCM, consists of five key elements. They are – strategy, process, model, information, and performance.

These five components are described below.

Strategy

Strategy refers to a clear plan, action, and goals. And these outline how a business intends to compete in a particular market or with an outcome or number of products or services. It includes devising and handling business processes. Also, how to reach performance targets, set organisation structures and information systems.

Process

A process refers to a series or set of activities to produce a result. These activities help operate and manage the entire supply chain. That includes links between operations and relevant best practices.

Model

There are many models in SCM. An SCM model will include management structures, department missions, and roles and responsibilities. Keep reading to find the most popular supply chain management models.

Information

Information is critical in supply chain management. In fact, IT systems and tools can support the supply chain. That can be through planning, execution, infrastructure maintenance, and facilitate decision-making.

Performance

Metrics or performance indicators help evaluate and effectively manage supply chains. Having a balanced set of process-level performance indicators can help supply chains reach targets.

How does Supply Chain Management Work?

To fully comprehend how it works, one needs to understand the supply chain management (SCM) process.

The SCM process involves almost every aspect of business operations, such as logistics, buying, and IT. Not only that, it integrates raw materials, finances, suppliers, manufacturers, wholesalers, retailers, and consumers into one seamless system.

The Supply Chain Management Process

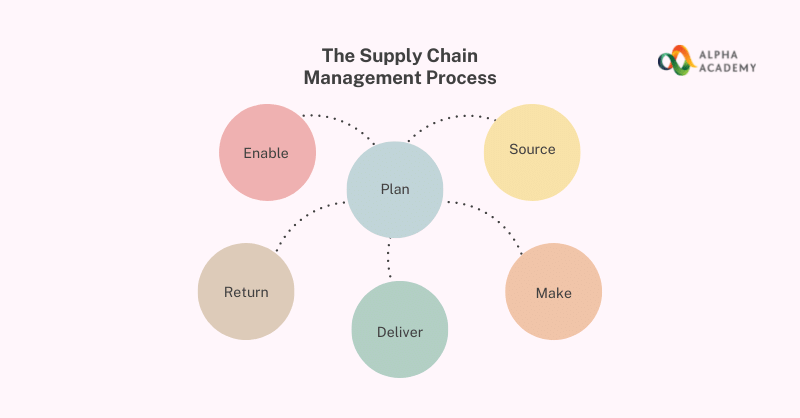

APICS or Association for Supply Chain Management endorses Supply Chain Operations Reference (SCOR) model. It’s a process reference model developed in 1996. It is now a cross-industry de facto process improvement diagnostic tool for the supply chain management.

SCOR is based on six distinct management processes to facilitate the supply side of the business. And they are – plan, source, make, deliver, return, and enable. So let’s explore these components and understand how they facilitate the supply chain management process.

Plan

The planning process includes all the activities needed to operate the supply chain and meet customer demand. For instance, it specifies requirements and compiles data about available resources. Also, it balances requirements and resources to assess planned capabilities. Yet another aspect is finding gaps in demand or resources and identifying actions to correct them.

Again, it helps determine metrics to measure whether the supply chain is efficient, and effective. Lastly, it helps deliver value to customers and meets company goals.

Source

Sourcing means procuring goods and services to meet planned or actual demand. The first step is to choose suppliers to provide the goods and services needed to develop or create the product. Then, establish procedures to monitor and manage supplier relationships.

Essential sourcing functions include ordering, delivery management, and receiving orders. Additionally, managing inventory and authorising supplier payments are also part of sourcing.

Make

Making involves transforming the product or service to a finished state. That means manufacturing, converting, or assembling materials. And they make finished goods or parts for other products. And the aim is to meet the planned or actual demand for the product. Also, this requires organising the activities needed to –

- accept raw materials

- manufacture the product

- check the quality

- package them for shipping

- schedule delivery

Deliver

Delivery is one of the most critical components of supply chain management. It involves coordinating customer orders, scheduling deliveries, dispatching loads, invoicing customers, and receiving payments. Having delivery and logistics services is pivotal for this purpose. And depending on the product or service, businesses might need various transportation modes such as road, air or rail for a seamless delivery system.

Return

This is part of post-delivery customer support. Return or reverse logistics is necessary to move goods from customers back to the sellers or manufacturers. It requires a network or process to take back any defective, excess, defect or unwanted products from the buyer. Essentially, reverse logistics helps the supply chain move forward.

Enable

The processes involved in enabling describe all the activities associated with SCM. These include –

- Business rules

- Performance management

- Data management

- Resource management

- Facilities management

- Contract management

- Supply chain network management

- Regulatory compliance management

- Risk management

- Supply chain procurement

Popular Supply Chain Management Models

In this competitive business environment, automating processes and effectively managing supply chains are essential for businesses to thrive.

However, with varying business needs, there is no one model fits all when it comes to supply chain management. Depending on the industry, product type, and resources, some supply chain models are more suited to some businesses than others. So it’s imperative to understand all the modes and decide which one works best for your business.

Here are some of the most used supply chain management models –

1. The continuous flow model

2. The fast chain model

3. The efficient chain model

4. The custom-configured model

5. The agile model

6. The flexible model

A short description of the supply chain models is given below.

The Continuous Flow Model

The continuous flow model offers stability in high demand situations and is built around efficiency. It is also known as repetitive-flow manufacturing. And the goal of this model is an optimal, balanced production line. Also, minimum waste, the lowest possible cost, on-time delivery and defect-free production.

This classic supply chain model is best suited for commodity manufacturing. For example, manufacturers who specialise in a product. And they produce it continually, with slight design fluctuation or alteration.

The Fast Chain Model

The fast chain model is known for responsiveness and flexibility. And this is ideal for manufacturers who change their product line frequently and for trendy products with short life spans. This model focuses on shortening the time from idea to market. And also on maximising forecast accuracy to reduce market mediation costs.

This model recognises the competitive advantage of being the first adopter in a cut-throat market. But the actual driver of the fast chain is the designer—and the marketing department. The fast-fashion industry is well known for utilising this method.

The Efficient Chain Model

The efficient chain model is intended for hypercompetitive industries. Because that’s where end-to-end or E2E efficiency is critical. This model relies heavily on forecasting production, commodity and raw material prices. These are used to utilise machinery assets properly and ensure product availability and perfect order fulfilment.

Mainly commoditised companies use this model to make production decisions based on expected sales for the production cycle. Also, in markets where competition is highly price-based. Because customers don’t perceive significant differences in their value proposals. As a result, high rates of asset utilisation often meet the key objective of this model to lower costs.

Also, missing a forecast can have a ripple effect, such as long lead times and inflated prices. Case in point, efficient chains are struggling with capacity issues in the post-pandemic world. And some causes are labour shortages, material unavailability, and delays.

The Agile Model

The agile method is ideal for companies that manufacture customised products with unique specifications for each product. However, this model requires excess production capacity. Also, the products and processes are designed for the smallest possible batches to be agile. That means it requires less automation and more expertise. And that extra human touch adds more value, allowing businesses to command higher prices.

The agile model can ramp up product volume. But after passing a certain volume threshold, they become uncompetitive. And agile businesses may show disadvantages from a pricing standpoint at higher volumes.

The Custom-Configured Model

As the name suggests, the custom-configured models provide custom configurations, particularly during assembly and production. Also, it’s considered a higher-touch model that can provide quick turnaround times and small batches of products effectively.

Examples of this model can be seen in products such as cars or other electronics. Because they can be configured with a limited combination of product specifications. Usually by combining parts or sub-assemblies.

It’s the combination of agile and continuous flow models. Usually, the processes before product configuration are managed under a continuous-flow supply chain model. Then the configuration and downstream processes operate as per the agile supply chain model.

The Flexible Model

The flexible model provides businesses with the freedom to meet high demand peaks and manage long periods of low volume movement. And it can accommodate high demand and low demand needs pretty easily.

So, it’s more suitable for companies that must meet unexpected product demands. Thus, adaptability is critical, and management should focus on ensuring flexibility. And flexibility can be supported by four main capabilities, they are –

- An additional capacity for critical resources,

- Rapid-response capability,

- Technical strengths in process and product engineering,

- A quickly reconfigurable process flow.

A business requires the right tools to implement the flexible supply chain model successfully. Also, it requires a wide supplier network or personnel with a deep knowledge base.

Key Features of Effective Supply Chain Management

The supply chain is one of the most prominent aspects of business for customers and consumers. Therefore, the better a company’s supply chain management is, the better it’s business reputation and sustainability.

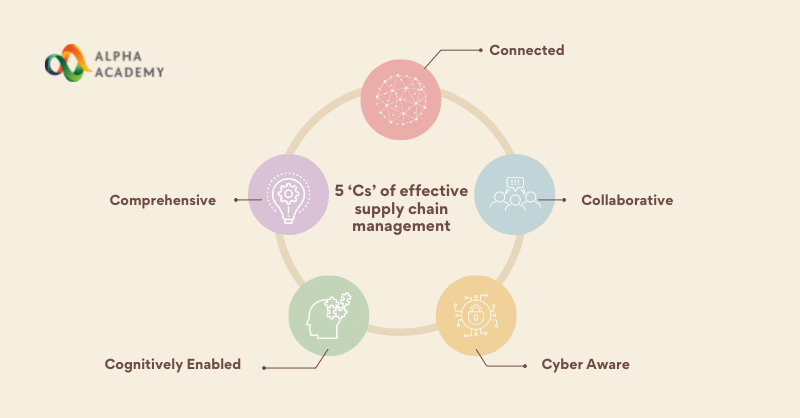

The Path to a Thinking Supply Chain defines the five ‘Cs’ of effective supply chain management. They are as follows –

Connected

A supply chain is an excellent source of data. Also, it’s essential to integrate all data sources and automate all documents across internal functions and process and supply chain partners. Connected means accessing both structured data and unstructured data. And a more traditional data set is available via conventional ERP and B2B integration tools.

Collaborative

When value creation in manufactured products happens outside the traditional manufacturing enterprise, collaboration is essential. Improving collaboration with suppliers in a digitally enabled environment requires the increasing use of cloud-based commerce networks. In addition, it facilitates multi-enterprise collaboration and engagement.

Cyber Aware

The supply chain systems and databases need protection from cyber intrusions and hacks. This is becoming more important as supply chains are going global and online. Therefore, not ensuring cybersecurity can become an enterprise wide concern pretty quickly.

Cognitively Enabled

The modern supply chain’s control tower needs to be cognitively enabled with the help of AI. This will help collate, coordinate, and take decisions across the chain in an automated and timely way.

Comprehensive

Analytical abilities must be scaled with information in real-time. Comprehensive and swift insights and data sharing facilitate new-age supply chains. Case in point, participation in cloud-based commerce networks is at an all-time high. And that means a major effort is underway to strengthen the analytical capabilities of SCM.

How to Start a Career in Supply Chain Management?

Now that you have a comprehensive understanding of SCM, let’s get you familiar with career possibilities. But first, you need to ponder if this is what you want to do.

Is Supply Chain a Good Career?

Yes, most people would agree that it’s a good career choice with plenty of job opportunities. The pandemic era has shown us exactly how crucial and necessary the supply chain is. Additionally, these jobs are usually well-paid and have a lot of career growth potential.

What Skills do You Need to Start a Career in Supply Chain Management?

Here are a few skills; possessing these will give you a head start in your SCM career.

Relationship Management

Building and maintaining mutually beneficial relationships with suppliers, vendors, and customers is crucial for logistics and supply chain management success. In a supply chain role, you will need strong communication skills, excellent interpersonal skills and negotiation skills.

Numerical Skills

Excellent numerical skills and statistics knowledge are pivotal in mane SCM roles. For example, as an SCM manager, you’ll need to manage inventory, sales, and company finances. Also, you’ll need to be proficient in Microsoft Excel and other relevant software to analyse and forecast data and communicate your findings or predictions.

IT Skills

In this era of digitalisation, roles in logistics and supply chain management often require specialist software like Enterprise Resource Planning (ERP). So being familiar with such software and acquiring relevant IT skills will come in handy.

Leadership Skills

Supply chain managers manage operations and oversee staff. So, experience in project or team leadership can help prepare you for a career in SCM.

Problem-solving Skills

Supply chain management requires constant assessment and evaluation of processes. In addition, supply chain managers are responsible for ensuring that everything runs efficiently. Hence, exceptional analytical and problem-solving skills help people succeed in an SCM role.

How to Pursue a Supply Chain Management Career?

Here’s a simplified, step by step path for starting a career in supply chain management.

1. Decide Your Area of Specialisation

There are many areas in supply chain management, such as purchasing, procurement, transport, technology, facilities, etc.

2. Select an Industry

Depending on the industry, supply chain roles can vary slightly. So you have a preference, it’s good to stick to it and be familiar with that industry.

3. Get a Relevant Degree in a Relevant Discipline

A bachelor’s degree in a relevant subject can be helpful. You can also get a Logistics and Supply Chain Management Skills Training Diploma to develop expertise in this area.

4. Grow Your Network

Set up a LinkedIn profile and connect to professionals working in supply chain management. Attend workshops and seminars, and connect with recruiters and HR professionals.

5. Apply for Internships

Getting an internship is an excellent way of getting your feet in the industry. Also, you get real-world experience and exposure while studying. So getting an internship can lead to a permanent position or even help you get your next job.

How Much Can You Earn from Supply Chain Management?

Do you find yourself thinking about how much supply chain managers make? An average supply chain manager makes £32,865 per year in the United Kingdom.

The highest-paying companies for Supply Chain Managers in the United Kingdom pay around £91,465 per year.

Some other careers in supply chain management and their average annual salary are as follows –

- Supply Chain Specialist – £31,087

- Logistics Associate – £23,144

- Inventory Manager – £32,982

- Logistics Manager – £39,866

- Warehouse Manager – £28,395

- Procurement Manager – £48,066

Conclusion

Supply chain management encompasses the flows of products, materials, services, information, finance, and relationships across all boundaries. It’s one complicated web that ensures the product reaches the customer successfully. In addition, it’s a rapidly expanding and competitive field.

Supply Chain Management Skills Training helps tackle day to day tasks in SCM and get ahead in your career. So if you are interested in a career in supply chain management, we recommend you take this course.

0 responses on "Supply Chain Management: What You Need to Know"